Useful programs

Содержание

- 1 Useful programs

- 1.1 Run script on rising or falling edge of the discrete signal

- 1.2 Реализация универсального таймера (TON TOFF)

- 1.3 Signalling (sound, relay, sms, viber, telegram) about connection errors

- 1.4 Moving average

- 1.5 PID - control

- 1.6 Running hours meter

- 1.7 Time Circulation algorithm (together with redundancy function)

- 1.8 3-point control for a valve or servo

Useful programs

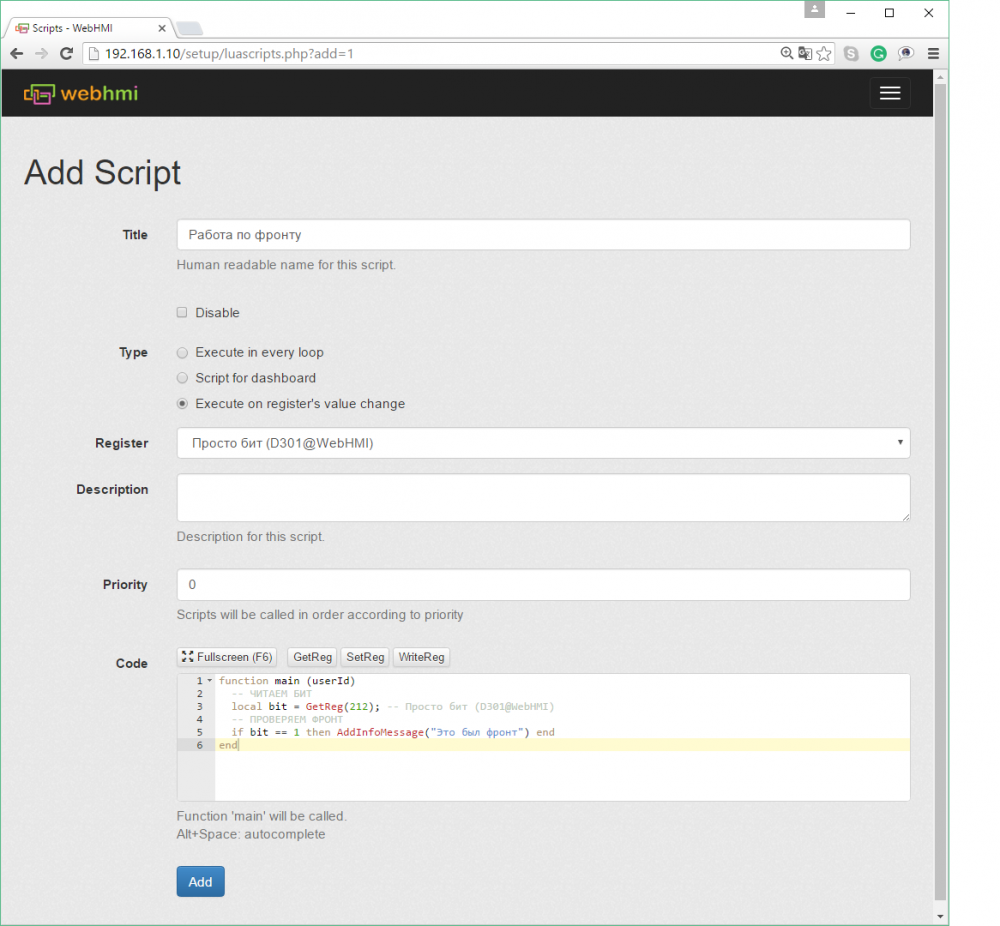

Run script on rising or falling edge of the discrete signal

The script needs to be called on register's change. Inside the script, you need to check the current state of this register and perform corresponding actions either on the front (current state = 1) or on the falling edge (= 0). Example of the script:

Реализация универсального таймера (TON TOFF)

Таймер сравнивает свое текущее состояние с состоянием на входе:

- текущее состояние = 0, вход = 1 - таймер включит выход через время задержки onDelay. Таймер TON получится если указать время offDelay = 0.

- текущее состояние = 1, вход = 0 - таймер выключит выход через время задержки offDelay. Таймер TOFF получится если указать время onDelay = 0.

Для работы таймера необходимо завести 2 DS регистра типа Unix time и Bit и присвоить им имена (алиасы) вида "<Имя1>", "<Имя1>_out". В первом будет хранится время след. переключения, во втором - текущее состояние таймера.

function TimerOnOff(bool_input, onDelay, offDelay, tmrAlias)

-- bool seconds seconds string

local outAlias = tmrAlias.."_out"

local curTmrState = (GetReg(outAlias) == 1) ; DEBUG("curTmr State "..tostring(curTmrState))

DEBUG("bool_input = "..tostring(bool_input))

if (bool_input == curTmrState) then

WriteReg(tmrAlias, now) ; DEBUG("timer input match state ")

return curTmrState -- as bool

elseif bool_input then

DEBUG("countdown for onDelay = "..(onDelay - (now - GetReg(tmrAlias))))

if now - GetReg(tmrAlias) > onDelay then

WriteReg(outAlias, 1)

DEBUG("detected ON state after delay ")

return true

end

else

DEBUG("countdown for offDelay = "..(offDelay - (now - GetReg(tmrAlias))))

if (now - GetReg(tmrAlias) > offDelay) then

WriteReg(outAlias, 0)

DEBUG("detected OFF state after delay ")

return false

end

end --

return curTmrState -- output rerurned as bool for simple usage in IFs

end -- function

Пример использования:

Например есть два дискретных входа с датчиками реле низкого и высокого давления. Их состояние читается и переводится в переменную типа bool для упрощения последующих операторов сравнения. Функция также возвращает bool, чтобы ее можно было сразу использовать в операторах сравнения без дополнительных операторов if.

DEBUG(" hotWater timer call ")

local DI2 = (GetReg(39) == 1) -- hotwater low pressure

local DI3 = (GetReg(40) == 1) -- hotwater high pressure

local hotWater = TimerOnOff((DI2 or DI3), 15, 15, "Tmr2") -- 15 seconds delay for both on and off .

-- or like this

if TimerOnOff(((GetReg("hotWaterLowPressure") == 1) or (GetReg(hotWaterHighPressure) == 1)), 15, 2, "Tmr2") then

-- do something

end -- simple timer in one row !

Signalling (sound, relay, sms, viber, telegram) about connection errors

It is possible to analyze the scan time by the script and if it exceeds the acceptable limit, signal it in different ways. Below is an example of processing a large scan time with signaling to the message buffer and Viber.

cntdownFlag = false; -- timer countdown flag

timeStmp = 0; -- time stamp

msgSent = false; -- message sent flag

function main (userId)

-- read inputs

local scan = GetReg(34); -- scan time

local c0 = GetReg(42); -- failed connection number

local SCANLIMIT = GetReg(886); -- scan time limit

local SCANDELAY = GetReg(887); -- error reaction time

--

if (scan == nil) or (c0 == nil) or (SCANLIMIT == nil) or (SCANDELAY == nil) then

ERROR("scan / c0 was read as nil");

return 0;

end

-- read time

local now = os.time()

-- message pattern

local msg1 = "Scan is long "..tostring(scan).." ".."ms, error in connection "..tostring(c0);

--

if (scan > SCANLIMIT) then -- scan above limit

if not cntdownFlag then

cntdownFlag = true

timeStmp = now

else

if (now - timeStmp) > SCANDELAY then

if not msgSent then

AddAlertMessage(msg1)

SendViberMessage(398044391, msg1) -- Женя

msgSent = true

end

end

end

else -- scan in normal

if (cntdownFlag == true) and msgSent then

AddInfoMessage("Скан вернулся к норме ")

SendViberMessage(398044391, "Скан вернулся к норме ")

msgSent = false

end

cntdownFlag = false

end

end -- main

In WebHMI there is a buzzer for the sound signal, and 2 output relays, which can be controlled for signaling (send a signal to the signal devices or the PLC about the problem).

Moving average

The moving average is useful for smoothing the values of parameters that have noises, pulsations.

Algorithm of the moving average:

at the beginning of the filter on the sample, N values are counted by the arithmetic mean, after reaching the end of the sample, one element is discarded (by dividing the sum by the length of the queue), a new one is added instead of it, and the amount is again divided by the length of the queue.

-- globals

mav_len = 20; -- queue length

queue_fill = 0; -- queue fill index

av_sum = 0; -- accumulator moving average

function main (userId)

local in_value, tmp_var, out_value = GetReg(26), 0, 0; -- read input

if (queue_fill < mav_len) then -- queue not filled

av_sum = av_sum + in_value; -- accumulating sum

queue_fill = queue_fill +1; -- and index

else -- now filled queue

tmp_var = av_sum / mav_len; -- store one element

av_sum = av_sum - tmp_var + in_value; -- subtract and add

end

--

if (queue_fill == mav_len ) then

out_value = av_sum / mav_len; -- get moving average

else

out_value = av_sum / queue_fill; -- arithmetic mean

end

WriteReg("Tout_mav", out_value) --

end

PID - control

An example of implementing a PID controller in WebHMI:

G_LIMIT = 100 -- output limit

--

function main (userId)

-- local vars

local now = os.time()

local nexTime = GetReg("nextPidTime")

local CYCLE_TIME = GetReg("pidCycleTime")

-- pid settings

local Kp = GetReg("Kp") -- Proportional part (DS1400@WH Valve control)

local Ti = GetReg("Ki") -- Integral time constant (DS1404@WH Valve control)

local Td = GetReg("Kd") -- Diff. constant (DS1408@WH Valve control)

local Err, dErr, iSum_Limit = 0, 0, 0

local Int_sum = GetReg("pidIntegral") -- integral accumulator

local intPart = 0 -- integral part

local G = GetReg("pidOut") -- pid output

-- process

local PV = GetReg(1436) -- power (PWR0@Scylar 8 INT)

local Sp = GetReg("targetPowerSp")

DEBUG_("seconds left for PID cycle = "..tostring(nexTime - now))

-- condition of work

local auto = (GetReg("auto_mode") == 1) -- auto mode is on (ds1176@WH Global)

local heatDemand = (GetReg("heatDemand") == 1)

if auto then

if heatDemand then

-- PID - loop

if (now >= nexTime) then

DEBUG_("PID compute cycle")

WriteReg("nextPidTime", now + CYCLE_TIME)

Err = Sp - PV -- get error

DEBUG_("sp pv Err = "..Sp.." "..PV.." "..Err)

dErr = Err - GetReg("pidPrevError") -- get error tendency

DEBUG_("dErr = "..dErr)

-- calc. integral limit

iSum_Limit = (G_LIMIT * Ti / Kp) / 5

DEBUG_("iSum_Limit = "..iSum_Limit)

-- PID loop

--check integral part

DEBUG_("prev Int_sum = "..Int_sum)

if (intPart <= iSum_Limit) and (intPart >= 0.0) then

Int_sum = Int_sum + Err -- accumulating integral of error

DEBUG_("added error to Int_sum ")

elseif Int_sum < 0 then

Int_sum = 0

else

Int_sum = iSum_Limit -- strict integral part

end

if (Ti == 0) then

intPart = 0

else

intPart = (1/Ti)*Int_sum

end

DEBUG_("new Int_part = "..intPart)

G = Kp * (Err + intPart + Td*dErr)

DEBUG_("Calculated G as "..G)

G = Round(G)

DEBUG_("Rounded G as "..G)

-- check output for limits

if G < 0 then

G = 0

end

if G > G_LIMIT then

G = G_LIMIT

end

WriteReg("pidPrevError", Err) -- remember previous error

WriteReg("dErr", dErr) --

WriteReg("pidIntegral", intPart) -- remember integral

WriteReg("pidOut", G)

WriteReg("posSPinput", G) -- output for valve position

end -- time stamp

else

DEBUG_("no heatDemand") --

G = 0

end -- heatDemand

-- DEBUG_("PID_out = "..G)

WriteReg("pidOut", G)

WriteReg("posSPinput", G)

end -- if auto

end -- main

-- rounding

function Round(var)

local integer, fraction = math.modf(var)

if fraction >= 0.5 then

integer = integer + 1

end

return math.floor(integer)

end

------ debug printing ------

thisScriptID = 45

function DEBUG_(str)

--ERROR("entered DEBUG_ in"..thisScriptID.." script");

local i = 0;

local tmp = "";

local id = tostring(thisScriptID);

local debug_id = GetReg("debug_IDs");

local capture_mask = "%s+(%d+)%s+"

while true do

i,_, tmp = string.find(debug_id,capture_mask,i+1)

if (i == nil) then

break -- not found

end

-- найдено

if (tmp ~= "0") then

-- found , check equality

if (tmp == tostring(thisScriptID)) then

DEBUG(str)

return 0

end

end

end

end -- DEBUG_

------------------------------

This algorithm is typical for use in PLCs. Because the regulator is run at regular intervals, i.e. diff. and int. the components are always computed on the same time scale, so it is not necessary to divide and multiply them by time to obtain the derivative and integral, we can select the time constants Ti, Td. In this algorithm, Ti is an inverse quantity (the larger its value, the smaller the contribution of the integral error)

Running hours meter

The running hour meter is convenient for automatically generating a message about the need for routine work for the equipment unit, changing the lead pump in the pumping group to equalize the operating time, and so on.

An example of the implementation of the run hour meter in WebHMI (the program runs in each scan):

-- globals

run_state = false; -- to remember current state

function main (userId)

-- locals

local check_mask = tonumber("0000100000000000",2); -- bit mask to check rotation bit in frequency inverter FC 51 Danfoss

local run_status = (bit.band(GetReg(109),check_mask) ~= 0); -- check result as a bool var

local now = os.time(); -- current system time

local time_diff = 0; -- time difference between current time and last call time

-- catching edge of the unit state

if (not run_state) and run_status then

WriteReg("P43StartTime", now); -- unit start time

end

-- count time

if run_state then

time_diff = (now - GetReg("P43StartTime")); -- calc. time diff.

WriteReg("P43RunTime", GetReg("P43RunTime")+time_diff); -- increase meter

WriteReg("P43StartTime", now); -- overwrite start point

end

run_state = run_status

end

The timekeeping registers and time stamps should be made non-volatile.

Time Circulation algorithm (together with redundancy function)

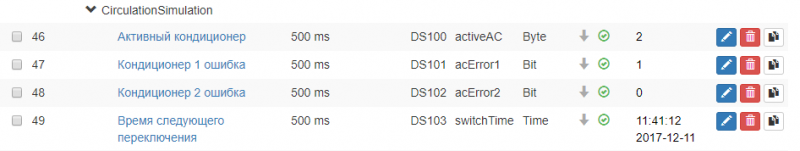

This algorithm is used in systems where it is necessary to alternate the operation of mechanisms (pumps, fans, air conditioners) over time, or on the run hour meters. For example, a set of 2 units is used, which must be alternated in time. If an error occurs on some unit, then the algorithm starts working only on the working (redundancy function). An example of setting the required registers is given below:

For simplicity and clarity, it is better to split the scripts into functional modules that can be quickly analyzed and placed in the right order in the program list. The first script looks at the errors and if they do not exist, the air conditioners alternate in time.

CIRCULATION_TIME = 30; -- for tests circulation time is short

function main (userId)

--[[

if there are no errors, then circulate over time

If there is an error on one of the air conditioners, it is excluded from the rotation

if there are errors on both, then we stand

--]]

local acError1, acError2 = (GetReg("acError1") == 1), (GetReg("acError2") ==1) ; -- errro on a/c #1 (DS101@webmi)

local switchTime = GetReg("switchTime"); -- next switch over time (DS103@webmi)

local now = os.time()

local curActiveAC = GetReg("activeAC"); -- active a/c (DS100@webmi)

if (not acError1) and (not acError2) then

-- work on circulation

if (now >= switchTime) then

if (curActiveAC == 1) then

WriteReg("activeAC", 2);

else

WriteReg("activeAC", 1);

end

WriteReg("switchTime", now + CIRCULATION_TIME);

end

elseif acError1 and (not acError2) then

WriteReg("activeAC", 2);

elseif acError2 and (not acError1) then

WriteReg("activeAC", 1);

else

WriteReg("activeAC", 0);

end -- if no errors

end -- main

The second script looks at what kind of conditioner is now active, and performs the necessary actions. In a script, this is just debugging, but there may be commands for controlling the infrared transmitter for issuing the desired command, writing to the message log and switching, etc.

function main (userId)

--[[

turn on selected a/c depending on pointer

--]]

local pointer = GetReg("activeAC"); -- active conditioner (DS100@webmi)

if (pointer==0) then

DEBUG("all off")

return 0

elseif

(pointer==1) then

DEBUG("turn on a/c #1");

else

DEBUG("turn on a/c #2");

end -- if

end

Also here you need a script that will expose the flags of errors of work on certain conditions, read the status of the protection devices, the error registers on the interface, and so on.

3-point control for a valve or servo

A 3-point method is used to control the position of the valve, servo, gate valve, etc., when 3 wires are used to control the drive - 'common', 'power UP', 'power - DOWN'. Such drives may or may not be equipped with end position sensors. Sometimes, in the absence of position sensors and low requirements for positioning accuracy, an algorithm can be used when the drive leaves down or up (either one position sensor or one command for a time longer than the valve's full travel time), initializes the coordinate, and then go to the specified position.

To determine intermediate positions, a calculated value is used, determined from the characteristics of the 'full path time', which can also be determined experimentally. As mentioned above, relatively complex and branched algorithms in WebHMI are better to divide into functionally complete and simple programs, the interaction and synchronization between them can be done using internal registers.

The

Below is a variant of 3-point control for a valve with 2 end sensors.

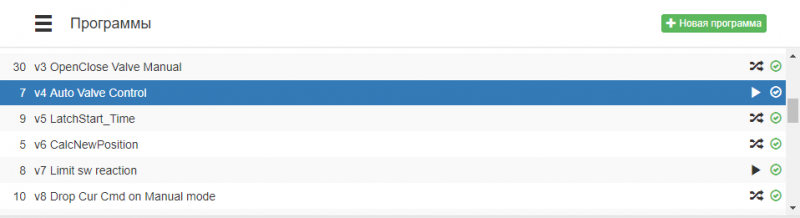

The program is divided into 6 parts:

- v3 OpenClose Valve Manual - manual control program,

- v4 Auto Valve Control - main program. do homing on very first call, and if set in current position are no equal move into the desired direction when set positions are limits, then keeps on current command till the limit switch is reached

- v5 LatchStart_Time - catches start time

- v6 CalcNewPosition - calculate path done like time since start time while valve in motion (this path is checked in v4).

- v7 Limit sw reaction

- v8 Drop Cur Cmd on Manual mode - when manual mode selected, clears current cmds

At the beginning of the programs, the order of the required execution order (v3..v8) is indicated, since the necessary order of program execution can change undesirable, for example, when sorting programs and inaccurate 'dragging' programs in the list. Thus, the prefix reminds you of the desired order, it can also reflect the functionality of the script - 'v' Valves, 't' - temperature control, etc. It is more convenient to navigate in large lists and refer to it.

Script are given below: </ p> v3

------- Manual control from dashboard buttons -------------------

function main (userId)

local button_value = GetReg("valveMan_code")-- pressed button code

local manual_mode = (GetReg("auto_mode") == 0) -- auto mode ON (ds1176@WH Global)

if manual_mode then

if (button_value == 10) then

WriteReg("openCmd", 1); -- opening command (DS1007@WH Valve control)

WriteReg("closeCmd", 0)

elseif (button_value == 5) then

WriteReg("closeCmd", 1); -- closing command (DS1008@WH Valve control)

WriteReg("openCmd", 0)

else

-- invalid code - all off

DEBUG("Read button value as "..tostring(button_value));

WriteReg("openCmd", 0)

WriteReg("closeCmd", 0)

WriteReg("inMotion_flag",0)

end --if

-- catching start position, and time

if (button_value == 10) or (button_value == 5) then

WriteReg("startPosition", GetReg("curPosition")); -- start position and time (DS1020@WebHMI 3point control)

WriteReg("startPosTime", os.time()) -- start time time stamp (DS1012@WebHMI 3point control)

WriteReg("inMotion_flag",1)

end

end -- manual_mode

end -- main -----------------------

v4

-- auto valve control ----

function main (userId)

local now = os.time(); -- cur time

local timeStmp = GetReg("endPosTime")

local auto_mode = (GetReg("auto_mode")==1)

if auto_mode then

-- check if very first run

if (timeStmp == 0) and (not home_mode) then

WriteReg("homingBit",1)

DEBUG("timeStmp = 0, homing needed! ")

end

local home_mode = (GetReg("homingBit") == 1)

local full_close = GetReg("LLsw")

if home_mode then

-- go down till low limit sw

DEBUG("giving home_mode close cmd ! ")

WriteReg("closeCmd", 1)

if (full_close == 1) then

DEBUG("full close ! ")

WriteReg("closeCmd",0)

WriteReg("endPosTime", now) to avoid homing again

WriteReg("homingBit",0)

WriteReg("curPosition", 0) -- current valve position

end

return 0 --

end -- home mode

--MAIN PART ----

DEBUG("-------- auto valve control ")

local openingStatus = (GetReg("openCmd") == 1)

local closingStatus = (GetReg("closeCmd") == 1)

local inMotionFlag = openingStatus or closingStatus

local target_dir= 0

local posSV = GetReg("posSetpoint"); -- position setpoint

local posPV = GetReg("curPosition"); -- current position

local startTime = GetReg("startPosTime");

local startPos = GetReg("startPosition");

local pathdone = 0;

local OpenSw = GetReg("HLsw"); -- full open limit sw

local CloseSw = GetReg("LLsw"); -- full close limit sw

DEBUG("posPV "..tostring(posPV).." pos SV"..tostring(posSV))

-- Already moving

if inMotionFlag then

-- full closed

if (closingStatus) and (posPV <= posSV) then

-- if 0 is setpoint then move till the physical limit sw

if (posSV == 0) and (not CloseSw) then

WriteReg("closeCmd", 1)

return 0 -- exiting, cmd will be off in v7 script

end

WriteReg("closeCmd", 0)

WriteReg("inMotion_flag",0)

end

-- full open ?

if (openingStatus) and (posPV >= posSV) then

--- if 100 is setpoint then move till the physical limit sw

if (posPV == 100) and (not OpenSw) then

WriteReg("openCmd", 1)

return 0 --exiting the command will be off in v7 script

end

WriteReg("openCmd", 0)

WriteReg("inMotion_flag",0)

end

-- stopped but not in position ?

else

if (posSV ~= posPV) then

target_dir = (posSV - posPV)/math.abs(posSV - posPV); -- определить знак

DEBUG_("target_dir = "..tostring(target_dir));

if (target_dir > 0) then

WriteReg("openCmd" , 1);

DEBUG_("will open...")

else

WriteReg("closeCmd" , 1);

DEBUG_("will close...")

end

WriteReg("inMotion_flag", 1) -- sets in motion flag

end

end -- auto mode motion control

end -- auto_mode

end -- main

v5

-- LatchStart_Time ---

function main (userId)

DEBUG("Entered latch start time and position");

-- Add your code here

local flag = (GetReg("inMotion_flag") == 1) ; -- in motion (DS1016@WebHMI 3point control)

DEBUG("motion flag = "..tostring(flag))

if flag then

DEBUG("now flag = 1")

WriteReg("startPosition", GetReg("curPosition")) -- start position (DS1020@WebHMI 3point control)

WriteReg("startPosTime", os.time()) -- start time stamp (DS1012@WebHMI 3point control)

end

end

v6

--- CalcNewPosition

-- constants

FULLPATH = 127 -- full close -> full open time

K = 100 / FULLPATH ; -- travel time to position coef.

function main (userId)

DEBUG("Entered #5 script, calc. cur position");

local now = os.time()

local open_sts = (GetReg("openCmd") == 1)

local close_sts = (GetReg("closeCmd") == 1)

local inMotionFlag = (open_sts or close_sts)

DEBUG("in motion flag = "..tostring(inMotionFlag))

local cur_dir = 0 -- current direction

local posPV = GetReg("curPosition") -- current position

--

local startTime = GetReg("startPosTime")

local startPos = GetReg("startPosition")

local pathdone = 0

-- moving now

if inMotionFlag then

-- detect direction

if open_sts then

cur_dir = 1

else

cur_dir = -1

end

pathdone = GetPathDone(startTime, now)

varPos = startPos + cur_dir*pathdone

-- check for valid range

if (varPos < 0) or (varPos > 100) then

DEBUG("new varPos calculaed outside limits, cur value "..tostring(varPos))

if (varPos < 0) then varPos = 0 end

if varPos > 100 then varPos = 100 end

end

DEBUG("startPos , pathdone = , new varPos "..tostring(startPos).." "..tostring(pathdone).." "..tostring(varPos))

WriteReg("curPosition", varPos); -- writing new position

end -- auto mode motion control

end -- main

function GetPathDone(startTime, curTime)

local curPos = (curTime - startTime) * K;

local remainder = curPos - math.floor(curPos)

if (remainder >= 0.5) then

-- rounding

curPos = math.floor(curPos) + 1

else

curPos = math.floor(curPos)

end

return curPos

end

v7

-- Limit sw reaction------------

function main (userId)

local now = os.time();

local open_sts = (GetReg("openCmd") == 1)

local close_sts = (GetReg("closeCmd") == 1)

local full_close = (GetReg("LLsw") == 1)

local full_open = (GetReg("HLsw") == 1)

if (full_open or full_close) then

if full_open then

WriteReg("curPosition", 100);

WriteReg("openCmd", 0);

WriteReg("valveMan_code", 0); -- for manual mode

end

if full_close then

WriteReg("curPosition", 0)

WriteReg("closeCmd", 0)

WriteReg("valveMan_code", 0)

end

WriteReg("inMotion_flag", 0)

WriteReg("endPosTime", now)

end

-- show current valve status

if (not open_sts) and (not close_sts) then

WriteReg("valveStatus", 0) -- stopped

elseif open_sts then

WriteReg("valveStatus", 1); -- opening

else

WriteReg("valveStatus", 2); -- closing

end

end -- main --------------------------------

v8

------ v8 Drop Cur Cmd on Manual mode ----

function main (userId)

local auto_on = (GetReg("auto_mode")==1) -- work on register change

if not auto_on then

DEBUG_("Dropped cmds in manua mode ! ")

WriteReg("openCmd", 0)

WriteReg("closeCmd", 0)

WriteReg("inMotion_flag",0)

end

end -- main