Purpose and application

Purpose

WEBHMI is a device that allows the user to effectively solve the task of monitoring the status of various engineering systems and objects, as well as remote management of them. On the one hand, WEBHMI has built-in support for popular protocols (such as Modbus) adopted by manufacturers of industrial equipment, on the other - a direct interface with the user through the built-in web server or through the API to other applications.

With WEBHMI it is possible to solve both simple tasks of the 'control panel' of equipment, in other words - the Human Machine Interface(HMI), and create monitoring systems (dispatching ) of distributed objects. Devices can communicate with each other as well as with the central dispatch server, transmitting data reflecting the state of the systems monitored to the upper level. WEBHMI has a fairly good means of ensuring its own reliability but is focused primarily on managing small (dozens of signals ) isolated or territorially distributed systems, rather than solving mission-critical management tasks at critical industrial facilities.

The concept of the system is as simple and transparent as possible. The device is delivered 'out of the box', without any artificial limitations and additional licenses, in a single configuration that provides the fullness of its functional capabilities. WEBHMI is a ready-made solution, combining an ultra-compact hardware platform that meets the requirements of industry standards, with preinstalled software that provides rapid deployment of WEB-monitoring projects of various objects, without special knowledge in the field of network technologies and programming skills.

The process of creating a WEBHMI project is very simple and intuitive, it is basically the same as that adopted in most modern SCADA systems and software of the operator panels. However, its unique feature is that the development tools are integrated directly into the user interface. Thus, the developer does not need specific software, he can work in any OS that is convenient for him, the project does not require compilation and downloading - all actions during the configuration process are immediately reflected in the system, and thanks to the web interface you can work with the project remotely.

Application

The simplest application is a local operator interface for monitoring industrial automation systems and equipment. The ability to manage various devices from any computer, tablet or smartphone, through a web browser, from anywhere on the network or via WiFi. In this case, WEBHMI can integrate into an existing network or act as a stand-alone access point.

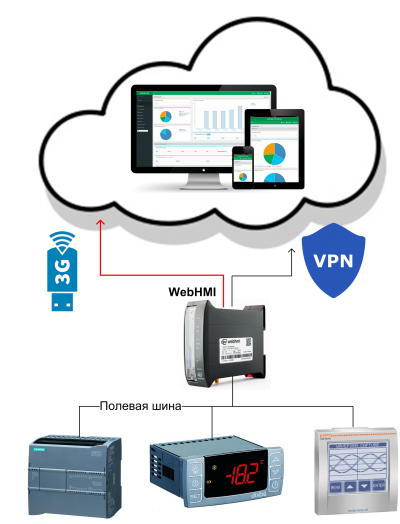

Вариант аналогичный первому, обеспечивающий доступ к интерфейсу через интернет, для мониторинга удаленных объектов. В случае отсутствия каналов связи наиболее рациональным решением будет подключить WEBHMI к мобильному 3G интернету, просто установив модем в USB разъем устройства. Для доступа к сайту потребуется получить у провайдера статический IP адрес или подключиться к какой-либо внешней сети с помощью VPN.

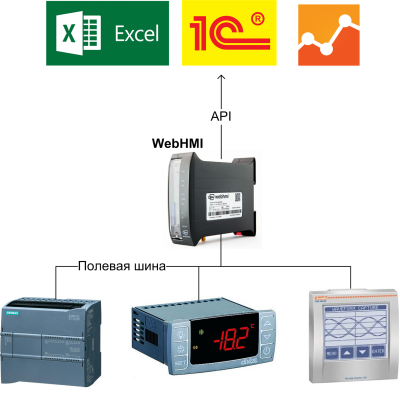

Следующий вариант предполагает возможность получения данных от техпроцесса непосредственно в целевое бизнес-приложение через интерфейс API

И наконец, вариант построения системы диспетчеризации распределенных объектов, предполагающей двухуровневую топологию, в которой WEBHMI выступают в качестве шлюзов данных нижнего уровня, передавая информацию на выделенный сервер, обеспечивающий её дальнейшую обработку и хранение. Подробнее об этой возможности можно узнать у поставщика устройства.