Working with cooling applience controller Danfoss AKCC 550

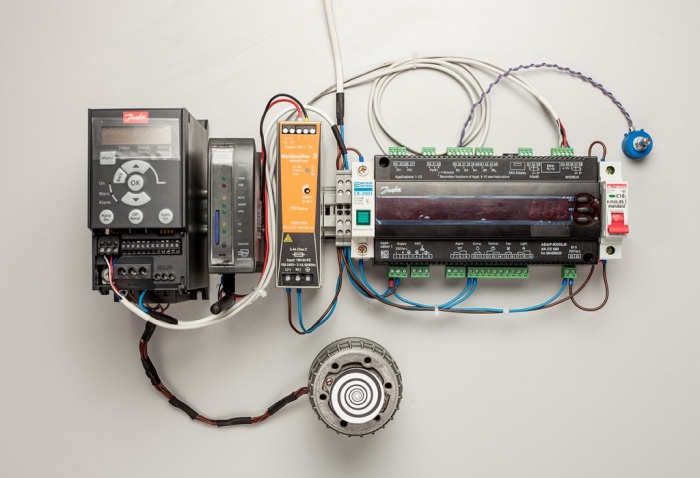

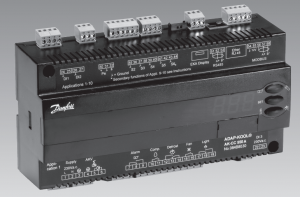

Remote monitoring and management of refrigeration equipment is becoming more relevant. To track malfunction in time, detect abnormal situations, moments of switching operation modes, keep statistics on energy consumption and other important parameters is very important. This is due to the ever-increasing requirements for the temperature storage of products, and, accordingly, to their quality, as well as to the energy efficiency of refrigeration systems. Of course, there are many different systems for remote management and monitoring of refrigeration equipment on the market, but they have a number of shortcomings. The main one is the focus on the management of a certain kind refrigeration unit or several of one type on the lower level. To manage huge installations (including not only refrigeration, but also other engineering infrastructure), it is necessary to use a global control system and to 'tie' to it smaller systems. As a rule, it is expensive and cumbersome. Using only one WebHMI gateway however, it is possible to combine all the refrigeration and other engineering equipment of the facility and link it to the upper level dispatch control system. Controllers Danfoss AK-CC 550 are a common model of controllers for cooling plants.

Controllers refrigeration equipment Danfoss AK-CC 550 has a kind of peculiar implementation of the communication interface:

- Auto-tuning for polling rate, i.e. after 3 incorrect requests from the 'master' (WebHMI), the module AK-CC 550 will be rebuilt to the next speed. The options are: 9600.19200, 38400. Thus, for WebHMI, it is sufficient to set any of these speeds in the connection properties.

- fixed byte transmission format - start bit, 8 data bits, parity bit, 1 stop bit

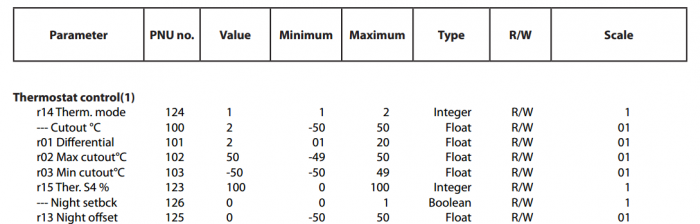

The instrument parameters in the user manual have an alphanumeric code, for example r14, u11. These codes are also displayed exactly on the instrument display. The network address of the module is set in parameter o03.

To obtain the Modbus parameter address, you must define its PNU number (Parameter number) and subtract 1. The complete list of parameters and corresponding PNU numbers is given in the document 'AK-CC550 Modbus Parameter Definitions'. This document is available on request.

[info@webhmi.com.ua].

A fragment of the parameter table is shown below.

Parameters named as "float" occupying one word in the address space are in fact integer values, scaled to a power of 10, their scale is indicated in the column scale. '01' means that you need to use a multiplier of 0.1 with an accuracy of one decimal place.

A video showing the management of the Danfoss' AK-CC 550 cooling controller and the management of the Danfoss frequency drive is available via link.